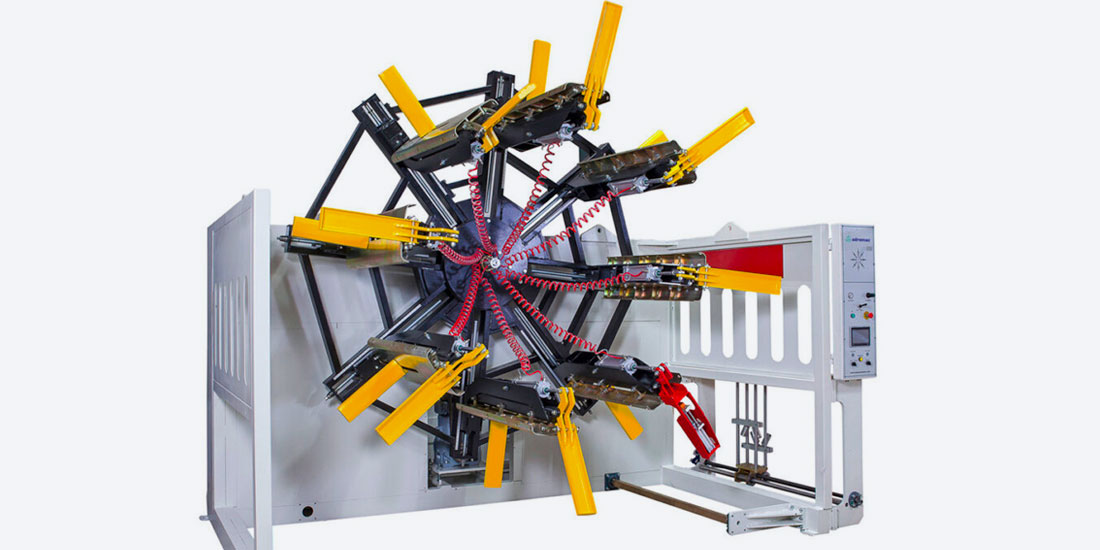

Semi-Automatic Pipe Coilers for Efficient and Precise Coiling

Adremac’s semi-automatic pipe coilers are designed to provide exceptional efficiency and precision in pipe coiling operations. These machines are equipped with servo motor-controlled Travers and torque-controlled working drums, ensuring consistent and smooth coiling even at high production speeds.

The design of the coiler drums has been optimized with a near-perfect round shape, which allows for better coiling, reducing strain on the pipes and ensuring that the final coil maintains its shape and integrity. This makes our pipe coilers ideal for industries working with PVC, PE, and other flexible pipes.

Learn more about the extrusion pipe coilers process: Plastic Pipe Extrusion Explained