What Makes a Plastic Pipe Production Line Good?

When it comes to choosing the best plastic pipe production line, several key factors determine the quality, efficiency, and reliability of the system. Whether you’re manufacturing PVC, PE, or PP pipes, selecting the right production line is crucial for ensuring long-term success.

1. Machine Quality

The most important factor to consider is the quality of the machinery. High-quality machines made from durable materials and components ensure consistent performance and reduce the risk of breakdowns. Well-assembled equipment guarantees that the production line runs smoothly, minimizing downtime and maintenance costs.

2. Production Capacity

Your production line’s capacity should meet your specific needs. Consider the types and sizes of pipes you intend to produce, as well as the desired production speed. Whether you’re manufacturing small-diameter pipes or large industrial pipes, your machine’s capacity must align with your business demands.

3. Energy Efficiency

Energy consumption is another critical factor. An energy-efficient production line not only reduces operational costs but also supports sustainable manufacturing practices. Look for systems that offer advanced energy-saving features, allowing your business to remain competitive while lowering environmental impact.

4. Ease of Use

The production line should be easy to operate and maintain. Controls should be user-friendly, with clear instructions for both operation and troubleshooting. Additionally, the machines should be easy to clean and maintain, ensuring minimal downtime and prolonging the lifespan of the equipment.

5. Customer Service

Good customer support is essential. Your equipment manufacturer should offer reliable and timely assistance, including spare parts availability and maintenance services. Strong customer service ensures that any issues are addressed quickly, keeping your production line operational and avoiding costly delays.

Other Factors to Consider When Choosing a Plastic Pipe Production Line

1. Pipe Material Type

Different types of plastic pipes, such as PVC, PE, and PP, require specific machinery configurations. The type of material you plan to process will dictate the equipment needed, so it’s important to select machines that are designed for the plastic type you’ll be working with.

2. Pipe Size

The size of the pipes you intend to produce will determine the size and configuration of the machines you need. Whether you’re producing small-diameter pipes for plumbing or large-diameter pipes for industrial applications, you’ll need to choose a production line capable of handling the desired pipe dimensions.

Additional Tips for Selecting the Best Plastic Pipe Production Line

- Compare Different Models and Manufacturers: Take time to compare various models and manufacturers to find the one that offers the best combination of quality, features, and support.

- Read Customer Reviews: Customer feedback can provide valuable insight into the performance and reliability of different machines.

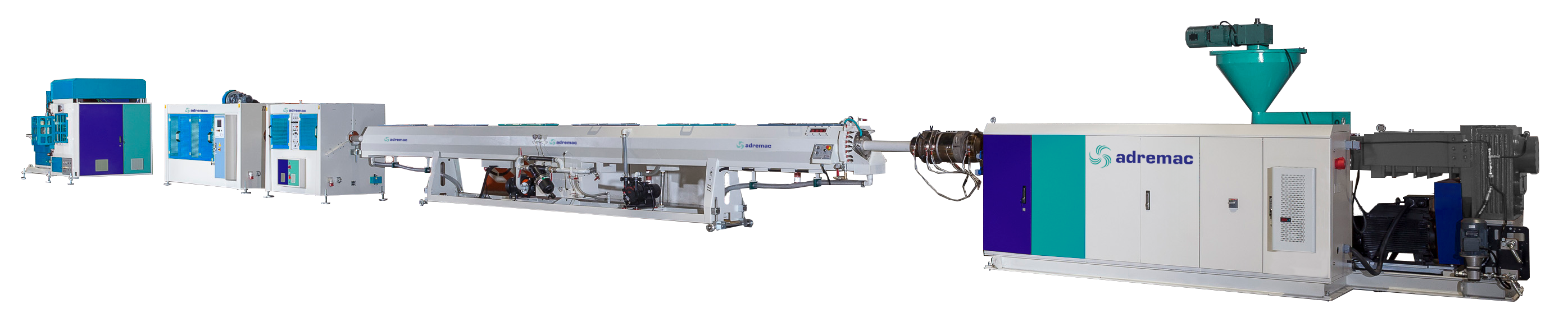

- Contact Us for References: Reach out to Adremac to see our references. This will help you better understand the quality of our machines, the manufacturing process, and give you the opportunity to see our machines in action.

By carefully considering these factors, you can select the best plastic pipe production line for your business. With Adremac’s range of high-quality machinery, you can be confident in finding the right solution to meet your production needs.