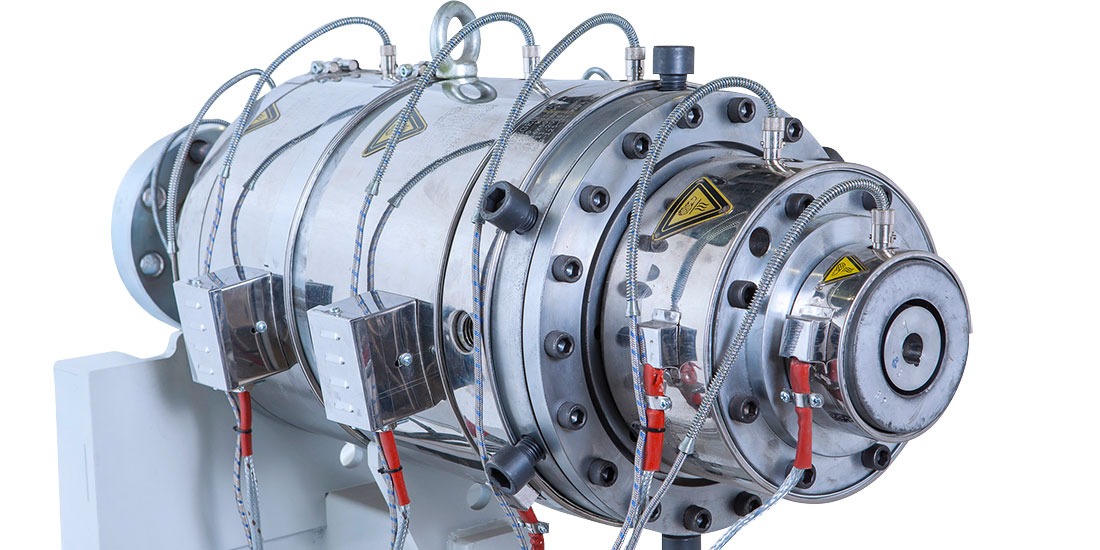

ADHED® Mono & Multilayer Die Heads for Superior Pipe Production.

The ADHED® mono and multilayer die heads are engineered for optimal high-output production in plastic pipe extrusion. Designed for versatility, these die heads cater to a wide range of production needs, ensuring consistent and superior pipe quality across different materials such as PE, PP, and PVC.

Detailed guide: Plastic Pipe Extrusion Explained