Pipe extrusion is a complex and essential process in modern manufacturing, especially when dealing with materials like PVC, PE, and PP. To achieve efficient production and high-quality outputs, having the right machinery and equipment is crucial. In this guide, we will explore the key components of the pipe extrusion process, including machinery, pipe cutters, and downstream equipment, all designed to optimize your production line.

Pipe Extrusion Machinery: The Backbone of Production

At the heart of any successful pipe production line is the machinery used. High-performance pipe extrusion machinery ensures that your production processes run smoothly, consistently, and efficiently. Whether you’re working with polyethylene extrusion or polypropylene extrusion, the machinery you select plays a significant role in the outcome. Having vacuum sizing tanks, haul-off belts, and extruders that meet your production needs will directly impact both the speed and quality of your output.

One critical element in this process is the vacuum tank, which ensures that pipes maintain their correct shape and dimensions during cooling. Additionally, the haul-offs for pipes and haul-off machines play a vital role in pulling the pipes through the line, keeping the operation running seamlessly.

Precision in Pipe Cutting: Tools and Techniques

Another crucial step in the pipe extrusion process is the cutting phase. Precision is essential here, and this is where pipe cutters come into play. High precision cutters are designed to achieve accurate and clean cuts, ensuring that pipes are cut to the exact length required.

Modern cutting systems like plastic pipe cutting machines or automatic pipe cutters offer advanced features like dustless chamfering and chipless cutting. These features not only improve the quality of the cut but also reduce material waste, making the entire production process more efficient.

For industries working with PPRC, PE, or PVC, having a reliable pipe cutter machine is essential for maintaining high production standards. Whether you need a rotary cutter or a planetary cutter, investing in high-quality cutting equipment will boost your production capacity and reduce downtime.

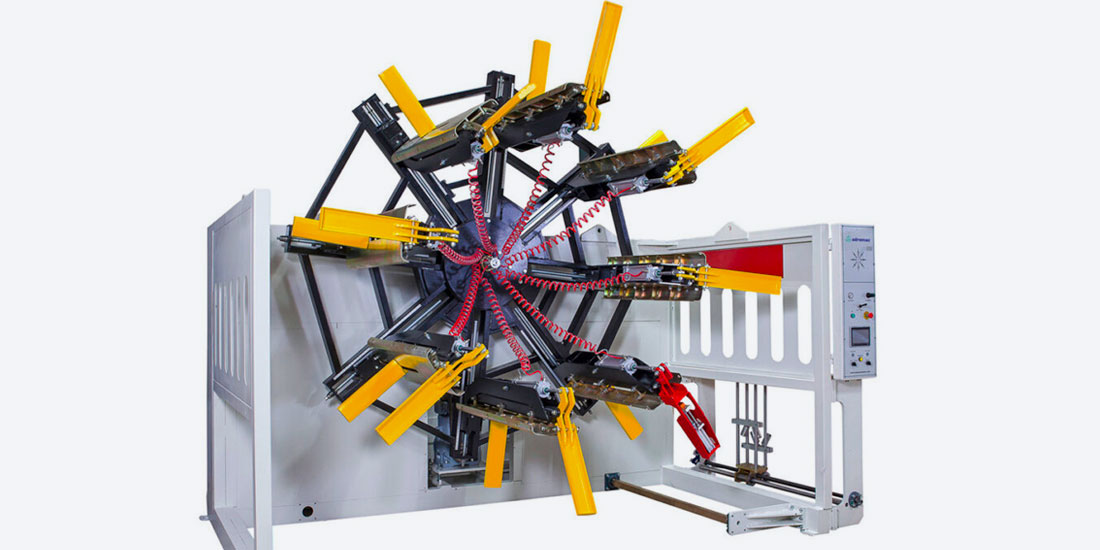

Coiling Solutions: Semi-Automatic and Automatic Pipe Coilers

Once the pipes are extruded and cut, the next step is to ensure they are properly coiled. This is where pipe coiling machines come into play. For industries dealing with plastic pipe extrusion, both semi-automatic coilers and automatic coilers offer efficient and reliable coiling solutions. These machines are essential for wrapping pipes in a way that maintains their structural integrity and reduces the risk of damage during transportation or storage.

Semi-automatic pipe coilers are ideal for smaller operations, while fully automatic pipe coilers are designed for high-volume production lines. By incorporating advanced technologies such as servo motor control, these machines ensure precise and rapid coiling, contributing to the overall efficiency of your production line.

Downstream Equipment for Enhanced Production

In addition to the primary machines like extruders and cutters, downstream equipment is equally important in ensuring the smooth operation of your pipe extrusion line. Components like vacuum spray cooling tanks, haul-off belts, and extrusion production lines all contribute to the overall efficiency of the process. Having the right pipe extrusion equipment in place will enhance the quality of your final product and reduce the need for maintenance and repairs.

Polyethylene extrusion processes and PVC pipe extrusion production lines particularly benefit from streamlined downstream equipment, as these components ensure consistent output and minimize waste. Whether you are working with polypropylene or PVC, having the correct downstream equipment is key to maximizing your productivity.

Why Choose Advanced Pipe Extrusion Solutions?

Choosing the right machinery and equipment for your pipe extrusion line is critical for success. Here are some reasons why investing in advanced pipe extrusion machinery and tools like pipe cutters and downstream equipment will benefit your production:

- Precision and Efficiency: High-quality machinery ensures that your pipes are produced with exact specifications and minimal waste.

- Increased Production Capacity: With automatic and semi-automatic solutions, you can scale your operations without sacrificing quality.

- Sustainability: Features like chipless cutting and dustless chamfering reduce material waste and contribute to a more sustainable production process.

- Durability and Longevity: Investing in durable, high-performance machinery means fewer breakdowns and longer machine life, reducing operational costs.

Conclusion

The pipe extrusion process requires a combination of high-quality machinery, precision cutting tools, and efficient downstream equipment. Whether you are working with PVC, PE, or PP, having the right tools in place will not only improve your production capacity but also ensure the quality and durability of your final product. By investing in advanced solutions like high precision cutters, automatic pipe coilers, and state-of-the-art pipe extrusion machinery, you can take your production to the next level.